One of a kind "leaning" Motor plate setup

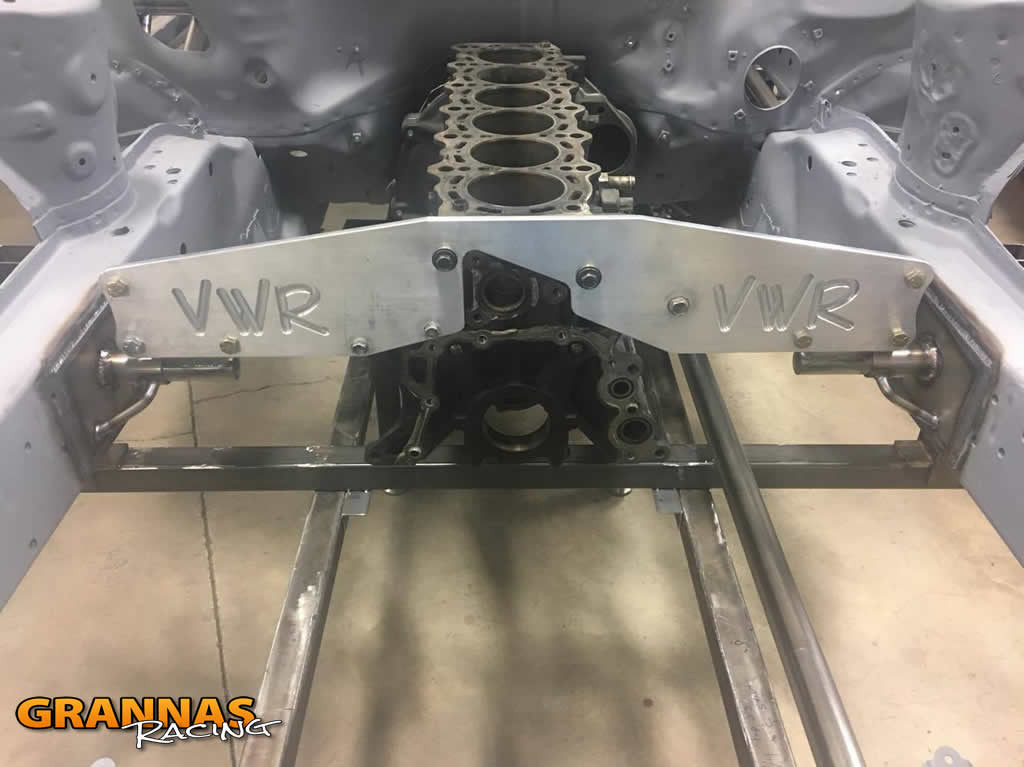

There is always complications when it comes to fitting into class rules... One of the issues I have had lately is cracking blocks right where the motor mounts were, I attribute this to the block flexing under extreme torque load. I was able to combat this partially by making custom upper motor mount brackets that used a wider footprint on the block. I felt like this was a workaround though, and new motor plates were the proper solution.

While motor plates are ideal, and give you a strong rigid mount, they also take away the ability to easily service your transmission. There is no real way to lean a motor back to do transmission service, as you loose that pivot point that the stock motor mounting location provides. Since I had to keep the factory floor in the car to fit into almost all class rules, doing motor plates would make it almost impossible to service the trans without pulling the motor. There would be no way to get to the top bellhousing bolts.

I talked to my chassis guy about the problem, and threw out a few suggestions, but what he came up with is just amazing. This is why I consider Doug Kline @ Precision Chassis the best damn chassis guy there is. I have never seen another setup like this done before... I am pretty sure it's the first of it's kind.

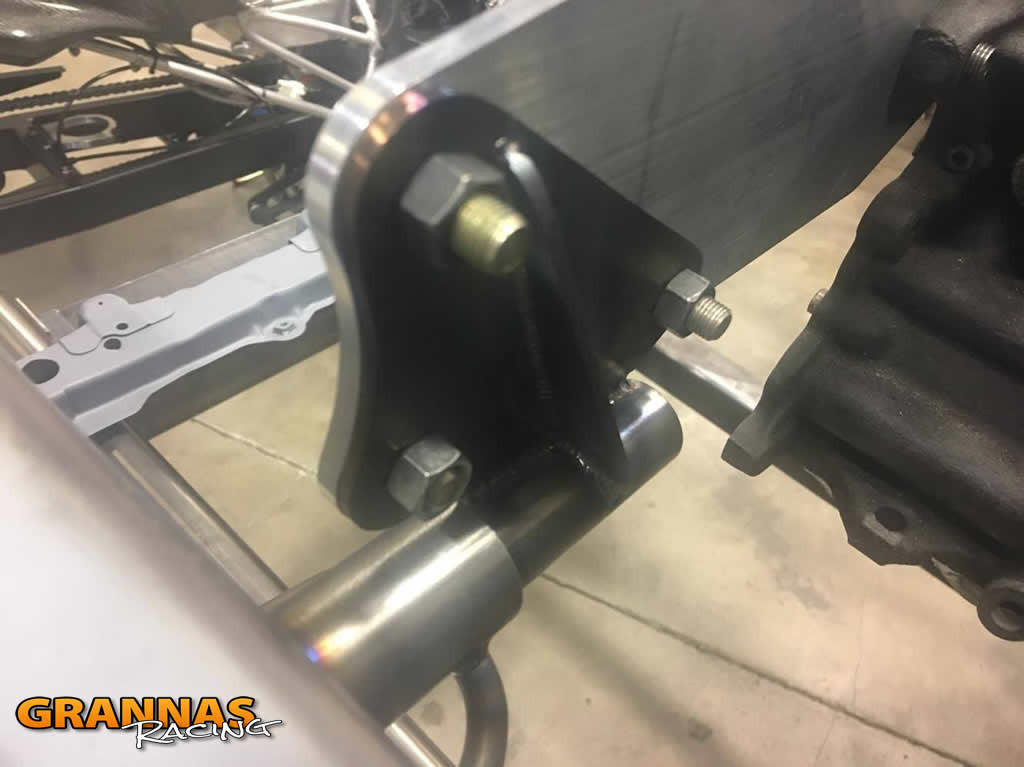

Doug fabricated a set of spindle mounts, which attach to the front frame rails and the front motor plate, which will allow the front motor plate to pivot. On the mid-plate between the engine and trans, he is going to make a bottom stop, which will allow the motor to be leaned to a pre-determined angle. This will allow me to service the transmission at the track if need be.

Pretty damn cool, right??!! More to come, stay tuned.

This car is going to be amazing when it is done!